Analyse des coûts des pyjamas en bambou imprimés sur mesure

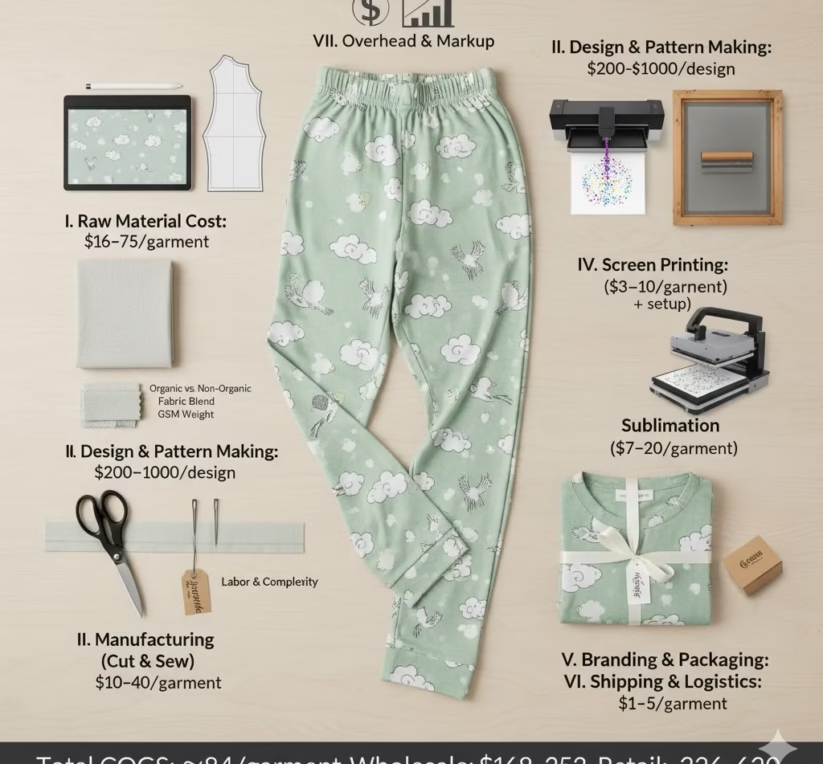

I. La formule du coût réel : Coût au sol

Contenu

Le cœur de l'article doit présenter la formule du "Landed Cost", qui est la seule façon de calculer la rentabilité avec précision.

II. Niveau 1 : Fabrication Coût (devis d'usine)

Il s'agit du prix unitaire indiqué par le fabricant, qui comprend plusieurs facteurs variables clés.

| Élément de coût | Facteurs clés influençant le prix | Gamme typique (par unité) |

|---|---|---|

| 1. Matière première (viscose de bambou) | Qualité/Certification : La qualité du bambou biologique certifié GOTS est généralement supérieure à celle de la viscose de bambou standard. | ~$2 – $4 |

| 2. Travail de coupe et de couture | Complexité : Les fermetures à glissière, les chaussons, les moufles rabattables et les volants augmentent les heures de travail et les coûts. | ~$3 – $6 |

| 3. Méthode d'impression (personnalisée) | Impression numérique ou sérigraphie : L'impression numérique est préférable pour les faibles QMo et les dessins complexes, mais elle est plus chère par pièce. | ~$1 – $3 |

| 4. Quantité minimale de commande (MOQ) | Le volume : Les commandes de gros volumes (par exemple, plus de 1000 unités) réduisent considérablement le coût unitaire. | ~$8 - $15 (Faible MOQ) |

| 5. Garnitures et accessoires | Qualité : Fermetures à glissière YKK (haut de gamme), étiquettes de taille tissées sur mesure et étiquettes d'entretien de marque. | ~$0.50 – $1.50 |

III. Niveau 2 : Coûts logistiques (les frais cachés)

Ces coûts sont souvent négligés par les nouvelles marques et peuvent détruire les marges s'ils ne sont pas pris en compte.

-

Fret : Expédition de l'usine (par exemple, en Chine ou au Vietnam) à votre entrepôt (par exemple, aux États-Unis). La méthode détermine le coût :

-

Fret aérien (cher/rapide) : Utilisé pour les échantillons ou les commandes urgentes.

-

Fret maritime (bon marché/lente) : Idéal pour les productions en grandes séries.

-

-

Frais de courtage en douane : Frais payés à un tiers pour s'occuper des formalités administratives, des droits de douane et du dédouanement.

-

Tractage/Livraison locale : Le coût du transport du conteneur du port à l'entrepôt final ou au centre 3PL (Third-Party Logistics).

-

Assurance : Protection de votre envoi contre la perte ou les dommages pendant le transport (les Incoterms tels que FOB ou CIF déterminent qui paie).

IV. Niveau 3 : Droits et taxes

C'est l'une des régions les plus imprévisibles pour les vêtements, en particulier le bambou.

-

Tarifs douaniers et droits d'importation : Calculé sur la base de la Code SH (code du système harmonisé) et le pays d'origine. Les droits de douane sur certains vêtements peuvent être très élevés (par exemple, dans la fourchette 15-25%+).

-

Exemple de calcul de tarif : Si un fabricant facture 10$ pour le pyjama, et le taux tarifaire est de 16%, le droit est 1.60$ par unité.

-

Taxe sur la valeur ajoutée (TVA) / Taxe sur les produits et services (TPS) : Applicable en cas d'importation dans des régions comme l'Europe, le Canada ou l'Australie.

V. Niveau 4 : Frais généraux calculés au prorata

Il s'agit de coûts uniques ou fixes qui doivent être répartis sur toutes les unités produites.

-

Échantillonnage : Le coût du proto-échantillon initial, de l'échantillon d'ajustement et de l'échantillon de production (par ex, 3 x$40 par échantillon).

-

Classement des patrons : Le coût de la création de modèles pour toutes les tailles (par exemple, 0-3M jusqu'à 5T).

-

Test de conformité (CPSIA) : Tests obligatoires d'inflammabilité, de plomb et de petites pièces pour les vêtements de nuit pour enfants. Il s'agit d'un coût fixe important (souvent $500 – $2,000+ par lot de style/tissu/couleur) qui doivent être ajoutés à votre coût total au sol.

VI. Conclusion et liste de contrôle de la rentabilité

-

La règle du 3-5x : Une fois que vous avez obtenu votre Coût d'atterrissage par unitéEn règle générale, vous devez le multiplier par un facteur de 3 à 5 pour obtenir votre prix compétitif. Prix de détail (par exemple, le coût d'atterrissage du $18 x 4 = $72Prix de détail).

-

Contrôle de rentabilité : Rappelez au lecteur que le prix de détail doit couvrir les coûts d'atterrissage, les frais de marketing (publicité) et les dépenses opérationnelles.

A propos de l'auteur

Xhiney, fondatrice de Petelulu, possède plus de 20 ans d'expérience dans la conception, la production et le commerce international de vêtements pour enfants. Elle a contribué à Vêtements pour enfants et Junior Xhiney a passé 17 ans à travailler avec des marques de vêtements pour enfants haut de gamme en Europe et aux États-Unis, apportant son expertise et son soutien.