Quality Control Essentials for Baby Clothing Suppliers in 2025

Ensuring the safety of baby clothing has never been more critical. In 2025, parents demand higher standards, prioritizing materials that are both safe and sustainable. Consumer trends reveal a 10% annual growth in the organic baby clothing market, driven by the rising demand for hypoallergenic fabrics. Natural materials like cotton and bamboo have become essential, reflecting the shift towards comfort and safety. As a supplier, you must meet these expectations without compromising on quality control. Companies like petelulu lead the way by blending innovation with rigorous safety protocols, setting benchmarks for the industry.

Key Takeaways

-

Follow safety rules like CPSIA, GOTS, and OEKO-TEX®. These make baby clothes safe and good for the planet.

-

Check for risks in production to remove dangers early. Use smart tools and work with experts to improve safety.

-

Use new technology like metal detectors and moisture controls. This makes clothes safer and more comfortable for babies.

-

Design baby clothes that look nice but are also safe. Make sure small parts are secure to avoid choking risks.

-

Work with trusted suppliers like petelulu for great materials. This helps your brand grow and builds customer trust.

Safety Standards in Baby Clothing

Key global safety regulations for 2025

In 2025, global safety regulations for baby clothing have become more stringent to address growing concerns about infant safety and comfort. As a supplier, you must stay informed about these evolving standards to ensure compliance and maintain consumer trust. Key trends shaping these regulations include:

-

Increasing demand for baby clothing free from hazardous embellishments to minimize choking or strangulation risks.

-

Government-mandated flame-resistant standards to enhance the safety of baby apparel.

-

A shift toward non-toxic materials, driven by parents’ preference for safer and more sustainable options.

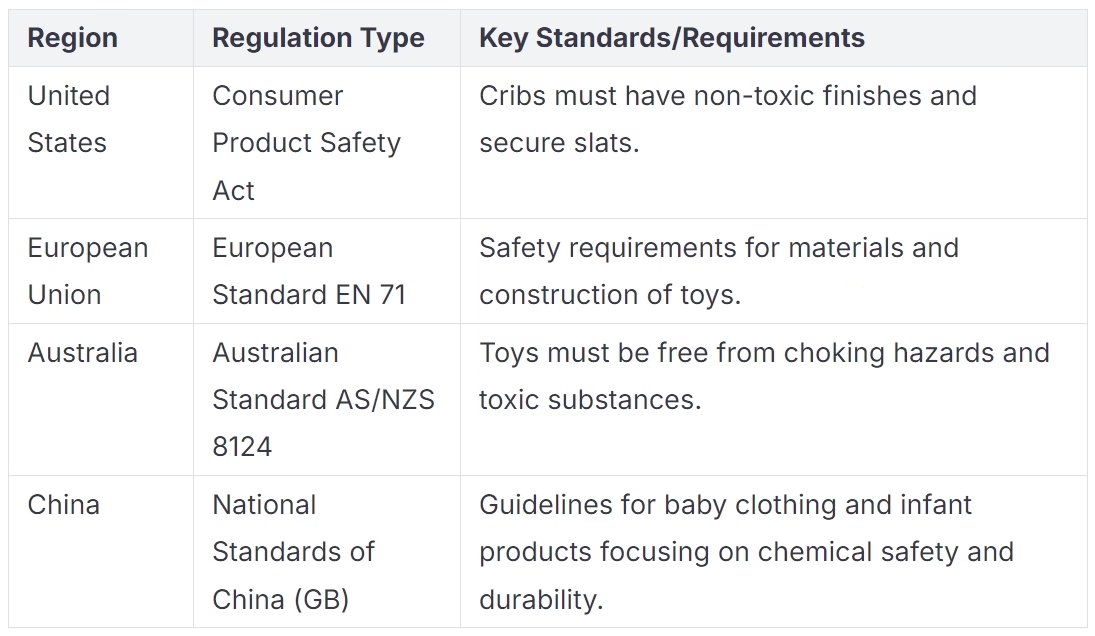

Governments worldwide have implemented region-specific regulations to safeguard infants. The table below highlights some of the key standards enforced in 2025:

Understanding these regulations is essential for maintaining quality control and ensuring your products meet the highest safety standards.

Compliance with CPSIA, GOTS, and OEKO-TEX®

Adhering to certifications like CPSIA, GOTS, and OEKO-TEX® is critical for baby clothing suppliers in 2025. These certifications validate your commitment to safety and sustainability, which are top priorities for modern consumers.

The Consumer Product Safety Improvement Act (CPSIA) enforces strict limits on lead content and prohibits harmful phthalates in baby clothing. For example:

Similarly, the Global Organic Textile Standard (GOTS) and OEKO-TEX® STANDARD 100 ensure that fabrics are free from harmful chemicals. These certifications test for over 1,000 substances to guarantee that every item is safe for human health. By complying with these standards, you can reassure parents that your products are both safe and eco-friendly.

petelulu’s approach to meeting safety standards

petelulu has established itself as a leader in baby clothing safety by adopting a proactive approach to quality control. The company prioritizes material selection, using organic and eco-friendly fabrics like 100% organic cotton and bamboo. This ensures that every product is gentle on a baby’s sensitive skin.

To maintain compliance with global safety standards, petelulu conducts thorough inspections at every stage of production. The company holds certifications such as OEKO-TEX® Standard 100, GOTS, and BSCI, which validate its commitment to safety and sustainability.

petelulu also incorporates innovative safety features into its designs, such as secure fastenings, flame-resistant fabrics, and non-toxic dyes. These measures not only meet but often exceed industry benchmarks, setting a new standard for quality control in baby clothing manufacturing.

By partnering with trusted suppliers like petelulu, you can ensure that your products align with the highest safety standards, giving parents peace of mind and building long-term customer loyalty.

Risk Assessments and Safety Checks

Identifying hazards in baby clothing production

Hazards in baby clothing production often stem from harmful chemicals, poor design, or inadequate material testing. You must identify these risks early to ensure the safety of your products. Research has revealed alarming statistics about chemical exposure in infants:

-

180 of these chemicals are linked to cancer in humans or animals.

-

217 are toxic to the brain and nervous system.

-

208 can cause birth defects or abnormal development in animal tests.

Specific chemicals like mercury, polyaromatic hydrocarbons (PAHs), and polybrominated diphenyl ethers (PBDEs) pose significant threats to infant health. These findings highlight the importance of rigorous quality control measures to eliminate such hazards from your production processes.

Implementing comprehensive risk assessment processes

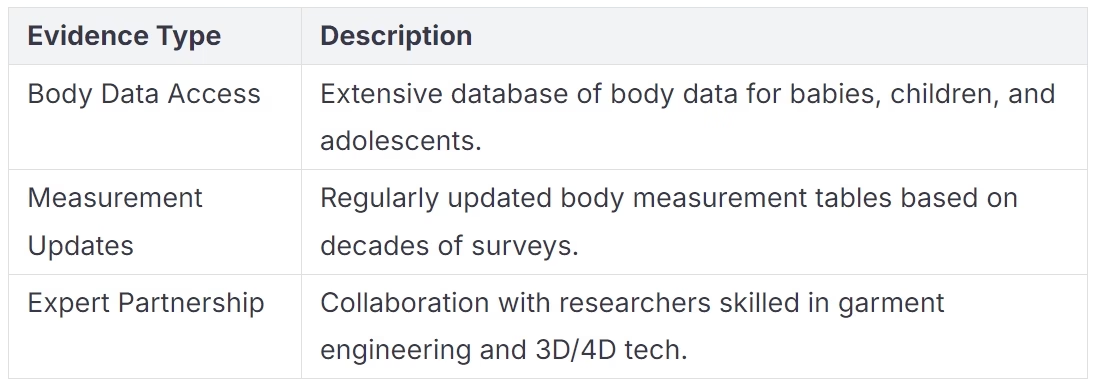

A robust risk assessment process ensures that every stage of production meets safety standards. You can achieve this by leveraging advanced tools and collaborating with experts. Facilities that implement these processes benefit from access to extensive body data for babies and children, enabling precise garment design.

These measures help you create clothing that fits well, minimizes risks, and adheres to global safety standards.

petelulu’s strategies for mitigating risks

petelulu employs a multi-layered approach to mitigate risks in baby clothing production. The company uses non-toxic, certified materials and conducts rigorous testing at every stage. Advanced technologies, such as 3D body scanning, ensure that garments are both safe and functional. Additionally, petelulu collaborates with industry experts to refine its processes and stay ahead of evolving safety requirements.

By adopting similar strategies, you can enhance your quality control efforts and build trust with consumers who prioritize their child’s safety.

Quality Control in Manufacturing

Metal detection and hazard prevention

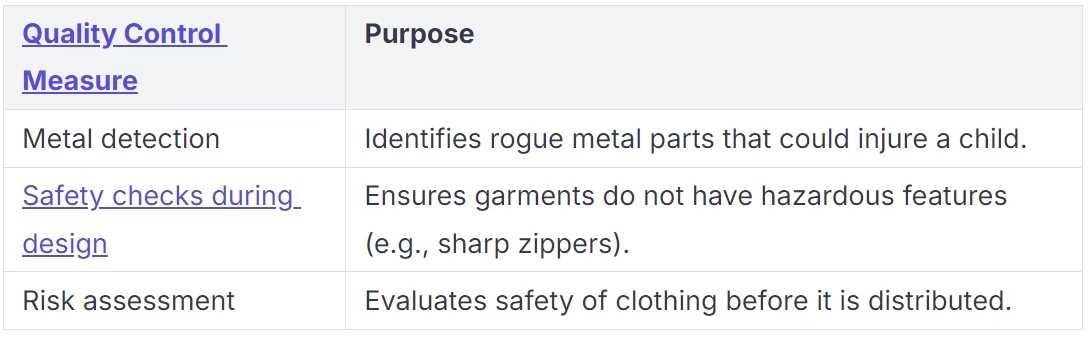

Metal detection plays a critical role in ensuring the safety of baby clothing. During manufacturing, rogue metal fragments from machinery or tools can accidentally embed themselves in garments. These fragments pose a serious risk of injury to infants. By implementing advanced metal detection systems, you can identify and remove these hazards before the clothing reaches consumers.

To prevent such risks, you should integrate metal detection as a standard step in your quality control process. This technology scans garments for metallic contaminants, ensuring that every piece is safe for use. Additionally, conducting safety checks during the design phase can help eliminate features that might inadvertently cause harm, such as zippers or fasteners with sharp edges.

By adopting these measures, you can minimize risks and build trust with parents who prioritize their child’s safety.

Ensuring chemical safety in fabrics and dyes

Chemical safety in baby clothing is non-negotiable. Infants have sensitive skin that can react adversely to harmful substances in fabrics or dyes. Studies reveal alarming statistics about the presence of toxic chemicals in children’s clothing. For instance:

-

A study by the Silent Spring Institute tested 93 products, including children’s clothing, for PFAS chemicals.

-

54% of the clothing samples contained detectable levels of fluorine, indicating the presence of PFAS.

-

Clothing items had higher PFAS levels compared to other tested categories.

-

PFOA, a phased-out PFAS chemical, was found in various products, primarily sourced from China.

To ensure chemical safety, you should source fabrics certified by organizations like OEKO-TEX® or GOTS. These certifications guarantee that the materials are free from harmful substances. Additionally, you can implement rigorous testing protocols to detect and eliminate toxic chemicals during production.

By prioritizing chemical safety, you not only protect infants from potential health risks but also align your products with the growing consumer demand for eco-friendly and non-toxic baby clothing.

Best practices for avoiding choking hazards

Choking hazards remain one of the most significant safety concerns in baby clothing. Small components like buttons, snaps, or decorative elements can detach and become life-threatening if swallowed. To address this, you should follow industry best practices to eliminate such risks.

One effective method is the 70 Newton pull test for buttons, which ensures that these components can withstand significant force without detaching. Additionally, you should avoid using embellishments that could easily break or loosen. Regular quality checks during and after production can further reduce the likelihood of choking hazards.

By adhering to these practices, you demonstrate a commitment to safety and quality control, reassuring parents that your products are designed with their child’s well-being in mind.

Aesthetics, Functionality, and Purpose

Designing for comfort and practicality

Comfort and practicality are essential when designing baby clothing. Babies have delicate skin that requires soft, breathable fabrics to prevent irritation. Organic cotton, certified by the Global Organic Textile Standard (GOTS), is a popular choice due to its hypoallergenic and breathable properties. This material ensures optimal comfort while meeting safety and environmental criteria.

Parents also value clothing that simplifies daily routines. Features like snaps, zippers, and magnetic closures make dressing and diaper changes more convenient. Research indicates that 65% of parents prioritize these practical elements when selecting baby clothing. Additionally, innovative designs, such as double zippers, enhance functionality without compromising comfort.

Choosing the right size and fabric further reduces potential irritants, ensuring a pleasant experience for both babies and parents. By focusing on these aspects, you can create clothing that meets the dual demands of comfort and practicality.

Balancing aesthetics with safety

Striking a balance between aesthetics and safety is crucial in baby clothing design. While parents appreciate visually appealing garments, safety remains their top priority. Decorative elements like buttons or embellishments must be securely attached to prevent choking hazards. Similarly, fabrics should be free from harmful chemicals to protect a baby’s sensitive skin.

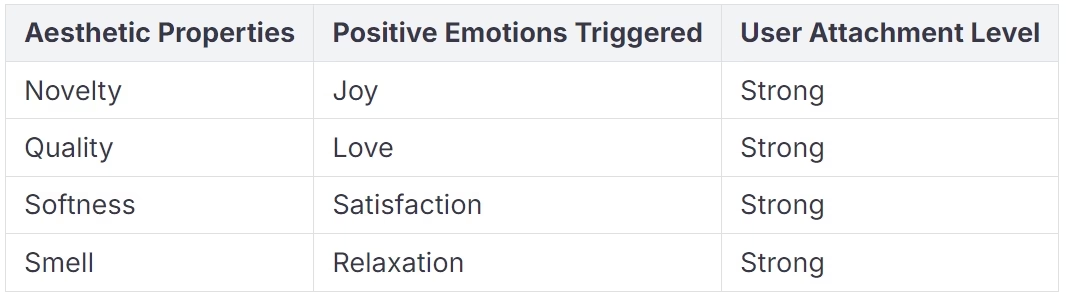

User feedback highlights the emotional connection parents form with well-designed baby clothing. The table below illustrates how aesthetic properties influence emotions and attachment levels:

By combining thoughtful design with rigorous safety measures, you can create products that resonate with parents on both functional and emotional levels.

petelulu’s commitment to high-quality design

petelulu exemplifies how to merge aesthetics, functionality, and safety in baby clothing. The company prioritizes quality control at every stage, ensuring that each garment meets the highest standards. By using organic fabrics like GOTS-certified cotton, petelulu guarantees comfort and safety for infants.

The brand also incorporates practical features, such as magnetic closures and secure fastenings, to simplify parenting tasks. At the same time, petelulu’s designs emphasize softness and visual appeal, fostering a strong emotional connection with consumers. This holistic approach sets a benchmark for the industry, proving that high-quality design can seamlessly integrate aesthetics, functionality, and safety.

Future-Proofing Quality Control

Leveraging technology for advanced quality checks

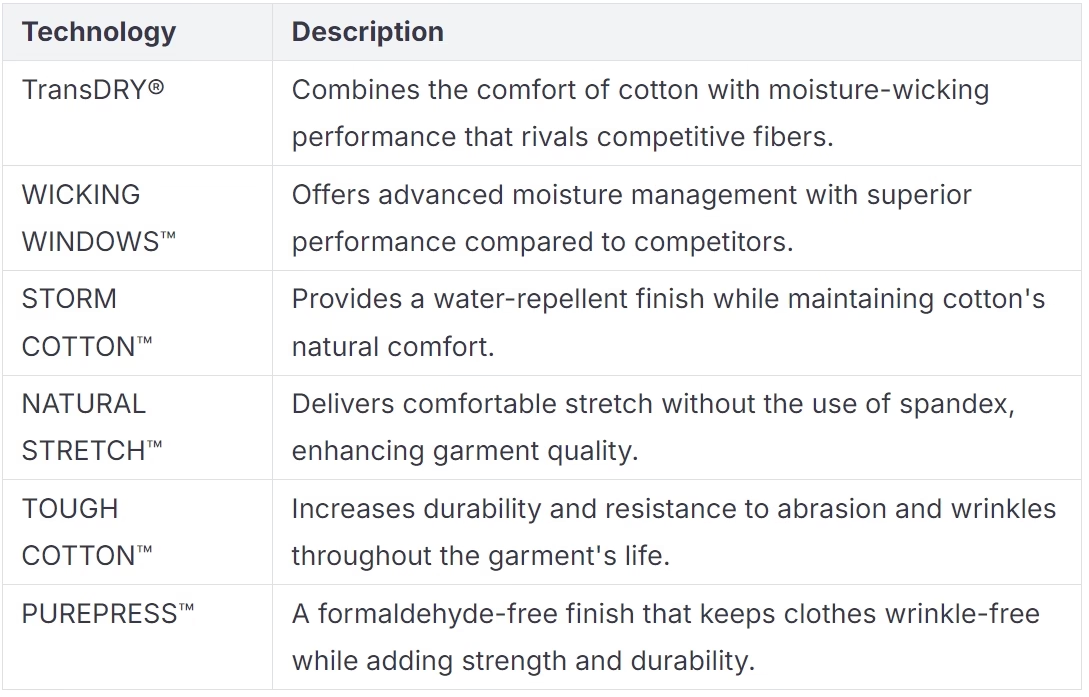

Technology continues to redefine quality control in baby clothing manufacturing. Advanced innovations allow you to detect flaws and ensure product safety with greater precision. Tools like TransDRY® and WICKING WINDOWS™ enhance fabric performance by improving moisture management, making garments more comfortable for infants. STORM COTTON™ adds water-repellent properties while preserving the natural softness of cotton.

Durability and safety remain critical. Technologies such as TOUGH COTTON™ and NATURAL STRETCH™ increase garment resilience and flexibility without compromising comfort. PUREPRESS™ offers a formaldehyde-free finish, ensuring wrinkle-free clothing that is safe for sensitive skin. By integrating these technologies into your production processes, you can elevate your quality control standards and meet the expectations of modern consumers.

Training teams to uphold quality standards

Your team plays a pivotal role in maintaining quality control. Regular training ensures they stay updated on the latest safety protocols and manufacturing techniques. Performance data highlights the impact of training initiatives, showing improved garment durability, chemical safety, and overall product quality.

For example, training programs focused on using technologies like PUREPRESS™ and TOUGH COTTON™ have led to garments with enhanced wrinkle resistance and abrasion durability. These improvements not only meet safety standards but also boost consumer satisfaction. By investing in your team’s expertise, you can create a culture of excellence that consistently delivers high-quality products.

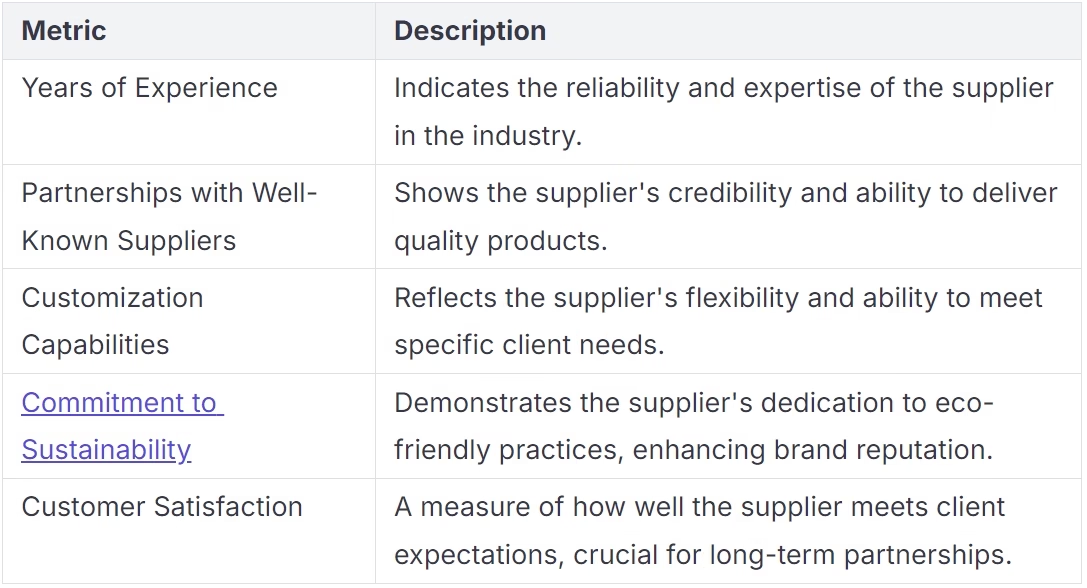

Partnering with trusted suppliers like petelulu

Collaborating with reliable suppliers strengthens your quality control efforts. Trusted partners like petelulu bring years of experience and a proven track record in the industry. Their commitment to sustainability and customization capabilities ensures your products meet both safety and aesthetic standards.

By partnering with suppliers like petelulu, you gain access to high-quality materials and innovative designs. This collaboration not only enhances your product offerings but also builds trust with consumers who value safety and sustainability.

Quality control remains the cornerstone of baby clothing manufacturing, ensuring safety, durability, and consumer trust. Proactive measures, such as implementing advanced technologies and adhering to standards like CPSIA and ISO 9001, reduce costs associated with recalls and enhance productivity. These efforts also build consumer confidence, fostering long-term success for brands.

petelulu exemplifies industry leadership by consistently exceeding safety benchmarks and integrating innovative practices. Their commitment to quality inspires suppliers to adopt rigorous standards, ensuring products meet the expectations of modern parents. By prioritizing continuous improvement, you can future-proof your operations and thrive in the evolving landscape of 2025.

Tip: Investing in quality control not only safeguards your brand reputation but also secures a competitive edge in the growing baby clothing market.

FAQ

What certifications should you prioritize for baby clothing in 2025?

Focus on CPSIA, GOTS, and OEKO-TEX® certifications. These ensure your products meet safety, chemical-free, and sustainability standards. They also build trust with parents who value eco-friendly and safe clothing for their children.

How can you prevent choking hazards in baby clothing?

Securely attach small components like buttons and snaps. Avoid drawstrings and detachable embellishments. Conduct pull tests to ensure durability. Regular inspections during production help eliminate risks and ensure compliance with safety standards.

What technologies improve fabric performance in baby clothing?

Use innovations like TransDRY® for moisture management and STORM COTTON™ for water repellency. TOUGH COTTON™ enhances durability, while PUREPRESS™ ensures wrinkle-free clothing without harmful chemicals. These technologies improve comfort and safety.

How do you ensure chemical safety in fabrics and dyes?

Source certified materials from organizations like OEKO-TEX® and GOTS. Implement rigorous testing protocols to detect harmful substances. Prioritize non-toxic dyes and finishes to protect infants’ sensitive skin.

Why is partnering with trusted suppliers important?

Reliable suppliers like petelulu offer certified materials and innovative designs. Their expertise ensures your products meet safety and aesthetic standards. Partnering with them strengthens your brand reputation and builds consumer trust.