Do esboço ao produto: As 7 etapas principais do fabrico personalizado

As a children’s apparel manufacturer, I see countless creative design sketches every day. For you—product managers and designers—turning an idea on paper into thousands of tangible garments can feel like a journey into the unknown. Your pain point is not knowing the full apparel production process and timeline, which can lead to delays, uncertainty, and even impact the entire go-to-market strategy for your marca de roupa para bebé. I want to tell you that this process isn’t a mysterious “black box.” By understanding our precise 7-step process, you’ll be able to make design decisions more confidently and build a transparent, efficient partnership with us.

The Pain Point: The Manufacturing “Black Box”

I know that once you send us a design sketch, the entire production process can feel like a black box to you. You’re unsure how long each stage will take, or what potential issues might arise, which creates anxiety when you’re planning your marketing de vestuário para bebés campaigns. A lack of transparency can lead to miscommunication, like misunderstandings about fabric choices or unexpected reworks during the sample development stage. All of this consumes precious time and budget, hindering you from bringing a great idea to market quickly.

Com 17 anos de experiência, a petelulu oferece uma gama completa de

serviços de fabrico desde a conceção até à entrega.

Comece do zero, crie a sua própria marca.

17+

servindo as 10 principais marcas americanas

15+

servindo as 10 principais marcas australianas

12+

ao serviço das 10 principais marcas europeias

Contacte-nos para obter o orçamento.👇

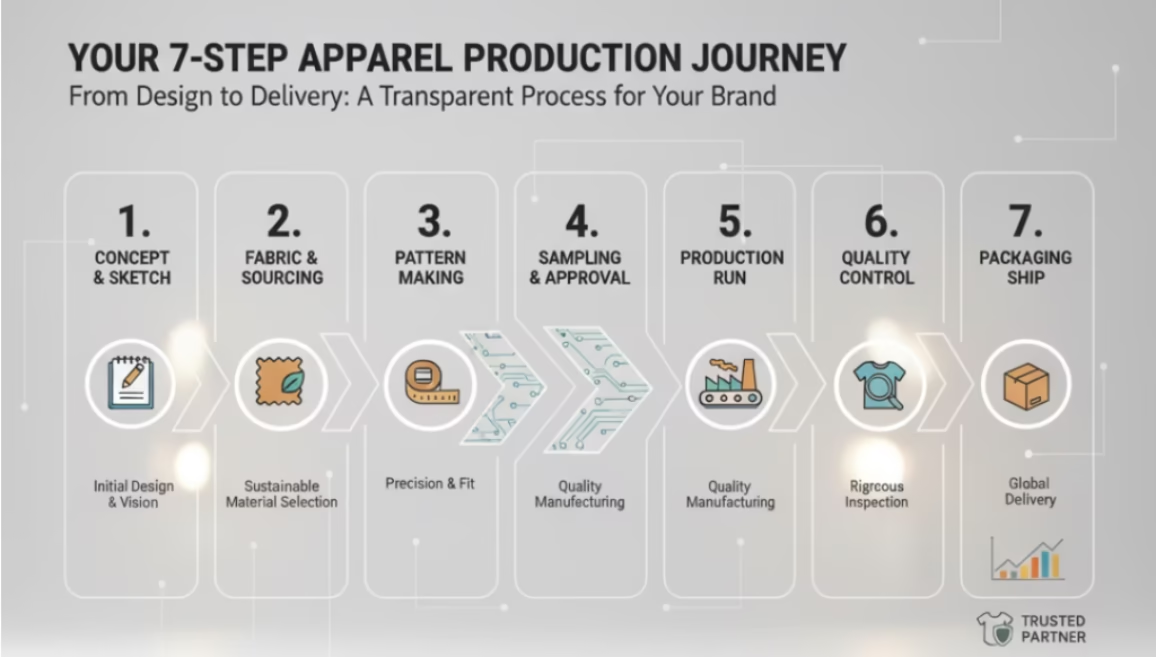

The Solution: Our Transparent 7-Step Custom Manufacturing Process

We firmly believe that a successful marca de roupa para bebé is built on a foundation of transparency and collaboration. That’s why we’ve created these 7 key steps to make every stage visible and ensure your designs are flawlessly translated into a finished product.

Step 1: Design Consultation & Tech Pack Creation

This is where the journey begins. We take the time to deeply understand your design sketch. We’re not just receiving a file; we’re learning about your inspiration, brand story, and target customer. We document every detail—from fabric type, color (Pantone numbers), size specs, to unique stitching and embroidery details—in a comprehensive technical package (tech pack). This tech pack is the blueprint for the entire project.

It’s worth noting that if you only have an idea but aren’t sure how to create your tech pack, we can help! You can send us your inspiration in the form of AI-generated images (from tools like Midjourney, DALL-E, etc.) or even hand-drawn sketches. Our experienced design team can then use your visual inspiration to create a detailed digital style file and communicate with you to ensure your creative vision is perfectly translated into the technical specifications needed for production.

Step 2: Fabric & Trim Sourcing

Once the tech pack is finalized, we begin sourcing. We find the exact fabrics and trims (like buttons, zippers, and labels) you’ve requested. With our 17 years of experience and global supply chain network, we can also offer high-quality, cost-effective alternatives to ensure your product’s quality is not compromised.

Step 3: Pattern Making & Grading

Our team of pattern makers creates the first paper pattern for your sample garment based on the tech pack and size chart. This is a critical process that determines the fit and drape of the clothing. We then grade the pattern to ensure that every size perfectly matches your original design intent.

Step 4: Sample Development (Prototype)

Now, your design takes physical form for the first time. We produce the first sample using the correct fabrics. We conduct a rigorous internal check before sending it to you. We encourage you to review the sample in detail and provide feedback. This is the last chance to refine the design and avoid major reworks later in production.

Step 5: Production Planning & Cutting

Once the sample is approved, we move into bulk production. We create an efficient production plan and use high-precision machinery to cut the fabric. Precise cutting is fundamental to ensuring size consistency across all garments, which is essential for your baby clothing brand’s reputation for quality.

Step 6: Sewing & Assembly

This is the core of production. Our skilled operators sew all the fabric components together on a professional assembly line. At every sewing station, we have quality control checks in place to ensure neat, secure stitching, and that all details match the tech pack.

Step 7: Finishing, Quality Control & Packaging

With the products assembled, we move to the final touches. This includes steaming, trimming any loose threads, attaching hang tags and labels. Every single garment then goes through our final comprehensive quality check to ensure it meets all of your quality standards. Finally, we package them according to your requirements and prepare them for shipment.

Key Factors & Timeline

To make the process even clearer, I’ve put together a brief table that will help you understand the general timeline for each step, which you can use to plan your marketing de vestuário para bebés campaigns.

| Step | Key Task | Approximate Timeline |

|---|---|---|

| 1-2 | Design Confirmation & Sourcing | 1-3 weeks |

| 3-4 | Pattern & Sample Development | 2-4 weeks |

| 5-7 | Bulk Production & QC | 4-8 weeks (depending on quantity) |

“Successful apparel supply chain management begins with clear communication and detailed planning, not by trying to fix errors in the production phase,”. This is the core philosophy of our process. A detailed tech pack and seamless communication are key to ensuring all projects are completed on time and on budget.

Com 17 anos de experiência, a petelulu oferece uma gama completa de

serviços de fabrico desde a conceção até à entrega.

Comece do zero, crie a sua própria marca.

17+

servindo as 10 principais marcas americanas

15+

servindo as 10 principais marcas australianas

12+

ao serviço das 10 principais marcas europeias

Contacte-nos para obter o orçamento.👇

Perguntas frequentes (FAQ)

Q: How long does it take to get a sample produced?

A: Typically, from the moment we receive your tech pack and confirm all details, it takes about 2-4 weeks to produce the first sample, depending on the design complexity and fabric availability.

Q: What is your Minimum Order Quantity (MOQ)?

A: Our MOQ varies depending on the garment type and fabric. We encourage you to contact us to discuss your specific needs. Our flexible production lines can accommodate different requirements, from small-batch to large-scale production.

Q: How do you ensure quality control during the production process?

A: We implement strict quality control at every stage. From fabric inspection upon arrival, to in-line spot checks during sewing, to a final comprehensive quality check before packaging, we ensure every single product meets your standards.

Conclusion

Transforming a creative sketch into a successful commercial product requires a transparent, efficient, and trustworthy partner. By understanding our 7 key custom manufacturing steps, you’ll no longer feel lost in the process. Instead, you’ll be able to confidently plan your next collection and focus on building a strong marca de roupa para bebé. We look forward to partnering with you to bring your vision to life.

Sobre o autor

Xhiney, fundadora da Petelulu, tem mais de 20 anos de experiência em design, produção e comércio internacional de vestuário para crianças. Colaboradora da Roupa de criança e Júnior Xhiney passou 17 anos a trabalhar com marcas de roupa de criança de gama alta na Europa e nos EUA, oferecendo conhecimentos especializados e apoio.