The 2026 Guide to CPC (Children’s Product Certificate) for US Baby Brands: A Manufacturer’s Perspective

A Children’s Product Certificate (CPC) shows your products are safe in the United States. If you are a children clothing manufacturer, you must prove each item follows safety rules. This helps protect your company and makes parents trust you more. Petelulu, a trusted children clothing manufacturer with seventeen years of experience, helps brands follow the rules and make safe, high-quality clothes.

Benefit/Risk | Description |

|---|---|

Reduced Legal Risks | Following the rules helps you avoid big fines that can hurt your business. |

Enhanced Consumer Trust | Safe products make parents feel better about buying from you. |

Improved Supplier Performance | Suppliers work harder to make better products when they follow the rules. |

Key Takeaways

Contents

- 1 Key Takeaways

- 2 What Is a CPC and Why It Matters

- 3 Does Your Product Need a CPC?

- 4 CPSIA Requirements for Children Clothing Manufacturers

- 5 Third-Party Testing and Compliance

- 6 Documentation and Issuing the CPC

- 7 Ongoing Compliance for Children Clothing Manufacturers

- 8 Best Practices and Petelulu’s Solutions

- 9 FAQ

A Children’s Product Certificate (CPC) is needed to sell kids’ products in the US. It shows your products are safe and follow the rules.

You should always have a written CPC for every product. This keeps your business safe and helps parents trust you.

Only use labs approved by CPSC for testing. This makes sure your products are safe and helps you stay out of trouble.

Change your CPC if you use new materials or suppliers. Keeping your papers up to date stops shipping problems and fines.

Work with skilled manufacturers like Petelulu. They can help you follow the rules and keep your products high quality.

What Is a CPC and Why It Matters

CPC Definition and Legal Role

A Children’s Product Certificate (CPC) is a paper that shows your product is safe for kids. If you make or bring in children’s clothes, you must give a CPC for each item. The US Consumer Product Safety Commission says a CPC proves your product passed lab tests and follows safety rules. You need to use test results from a CPSC-accepted lab to make the certificate. You cannot sell children’s clothes in the US without a CPC. Online stores like Amazon also ask for a CPC before you can list your products.

Tip: Always keep a written CPC for every product you sell. This helps protect your business and shows you care about safety.

Legal Responsibility | What You Must Do |

|---|---|

Use lab test results from a CPSC-accepted lab to certify your product | |

Written Documentation | Give a written CPC for each children’s product you sell |

Dependency on Testing | Only make a CPC after passing tests from a third-party lab |

Marketplace Compliance | Send a CPC to places like Amazon for children’s clothing |

Who Needs a CPC in 2026

If you make or import things for kids 12 or younger, you need a CPC. This rule is not just for toys. It covers clothes, jewelry, furniture, and many baby items. If you are a children clothing manufacturer, you must make sure every product follows these rules.

Children’s Toys |

Children’s Furniture |

Children’s Apparel |

Children’s Jewelry |

Toy Vehicles |

Baby products (pacifiers, teething toys, bottles, etc.) |

CPC vs. GCC: Key Differences

You might hear about both CPC and GCC. These certificates are not the same. A CPC is for things made for kids 12 and under. A GCC is for products anyone can use. The CPC needs testing at a CPSC-approved lab. The GCC does not need this kind of testing.

Feature | Children’s Product Certificate (CPC) | General Certificate of Conformity (GCC) |

|---|---|---|

Target Audience | Products for children aged 12 or younger | General use products |

Testing Requirement | Needs test results from a CPSC-approved lab | Does not need third-party testing, but must be based on a reasonable testing program |

Language Requirement | Must be in English | Not specified |

Remember: If you sell children’s clothing in the US, you need a CPC, not a GCC.

Does Your Product Need a CPC?

Children’s Product Criteria

You must check if your product is designed for or intended for children. The law says you need a Children’s Product Certificate (CPC) for any item made for kids, including clothing. If you do not have a CPC, you can face shipment delays or even have your goods stopped at ports. As a children clothing manufacturer, you must follow these rules to avoid problems and keep your business running smoothly.

Products that need a CPC include:

Children’s toys

Clothing

Furniture

School supplies

If you make children’s sleepwear, you must meet extra safety rules. For example, sleepwear must follow standards like 16 CFR part 1615 or 1616. These rules are different from those for regular clothing.

Age Grading and Scope

Age grading helps you decide if your product counts as a children’s product. The CPSC gives Age Determination Guidelines to help you. These guidelines show if your product is mainly for children 12 years old or younger. If your product fits this group, you must get a CPC. Age grading also helps you check if your product is safe and right for the age group you want to serve.

Tip: Always review the CPSC Age Determination Guidelines before you start making or selling a new children’s item.

Common Misunderstandings

Many people think only toys need a CPC. This is not true. Any product for children, like clothing or school supplies, needs a CPC. Some believe regular clothing does not need testing, but all children’s apparel must meet safety standards. You should not skip the CPC process, even if your product seems simple.

Myth | Fact |

|---|---|

Only toys need a CPC | All children’s products, including clothing, need a CPC |

Regular clothes are exempt | All children’s apparel must meet safety standards |

Sleepwear is the same as clothes | Sleepwear has extra rules and testing |

CPSIA Requirements for Children Clothing Manufacturers

CPSIA Rules for Apparel

You have to follow strict rules to make or sell children’s clothing in the US. The Consumer Product Safety Improvement Act (CPSIA) sets these rules to keep kids safe. If you are a children clothing manufacturer, you need to test your products at different times. You must check the fabric, seams, trims, and finished clothes. Each step helps you find problems before selling your products.

Here is a table that shows the main testing steps:

Testing Stage | Description |

|---|---|

Fabric Testing | Fabrics must pass flammability tests, even after washing. |

Prototype Testing | Seams and trims are checked before you start mass production. |

Production Testing | Each batch must pass flammability tests before shipping. |

Compliance Steps | Description |

|---|---|

Pre-Production Inspection | Check raw materials and processes to prevent unsafe products. |

Pre-Shipment Inspection | Review finished goods for quality and correct labeling. |

Certification | Provide a CPC for each batch and keep records for audits. |

You must use third-party testing from CPSC-accredited labs. You should keep your test results and certificates organized. Regular audits help you find and fix problems early. If you do not follow these rules, you can get in trouble with the law. Your brand’s reputation can also be hurt. The CPSC can recall unsafe products, which costs money and trust.

Petelulu helps you at every step. Our team uses certified labs and keeps good records. We follow a strict quality control system. You can trust your products meet all CPSIA rules.

Note: Sustainable manufacturing helps you meet CPSIA standards. If you use organic cotton or recycled polyester, you lower the risk of unsafe chemicals. Petelulu picks safe, eco-friendly materials and keeps a clear supply chain.

Lead, Phthalates, Flammability

You must control the levels of harmful substances in your products. CPSIA sets strict limits for lead, phthalates, and flammability. These rules protect children from dangerous chemicals and fire risks.

Here is a table with the main limits:

Substance | Maximum Allowable Limit | Applicable Products |

|---|---|---|

Lead Content | 100 ppm | All children’s apparel and sleepwear (zippers, buttons, snaps) |

Lead in Paint | 90 ppm | Screen prints and painted surfaces |

Phthalate Content | 0.1% | Sleepwear, bibs, and some apparel |

Flammability | Must comply with 16 CFR 1610 | All clothing for children 12 years or younger |

You must test every part of your product, including trims and prints. If you use safe, certified materials, it is easier to pass these tests. Petelulu uses OEKO-TEX and GOTS certified fabrics. We avoid harmful chemicals and pick safe dyes and trims. Our sustainable practices help you meet CPSIA limits and build trust with your customers.

Tip: Pick suppliers who give you certified, safe materials. This makes following the rules easier and protects your brand.

Labeling and Tracking

CPSIA says you must label and track every children’s clothing item. Labels help you find products if there is a problem. You must put important details on each label.

Requirement | Description |

|---|---|

Manufacturer/importer name | Show who made or imported the product. |

Location and date of production | List where and when you made the item. |

Manufacturing process details | Include batch or run number. |

Additional identifying info | Add details like the factory address if needed. |

You must add a tracking label to every item. The label should have your company name, production location, and date. You should also add batch numbers or other details that help you find the source of each product. This makes recalls faster and protects your business.

Petelulu helps you follow these rules. We add clear, accurate labels to every garment. We keep good records so you can trace every batch. Our team uses sustainable practices, like organic cotton and recycled polyester, to support safe and ethical production.

Reminder: Good labeling and tracking protect your brand and help you act fast if there is ever a safety issue.

If you are a children clothing manufacturer, you must follow CPSIA rules to keep kids safe and your business strong. Petelulu’s certified, sustainable approach makes following the rules simple and reliable.

Third-Party Testing and Compliance

Choosing a CPSC-Accepted Lab

You need to pick a lab that follows CPSC rules for children’s clothes. This makes sure your products pass safety tests. Here are steps to help you choose:

Make sure the lab is approved by CPSC for every test you need.

Check if the lab’s price covers only the tests you must do.

Ask the lab how you can spend less on testing. Some labs use composite testing, which helps save money.

A good lab partner helps you avoid mistakes and delays. You should keep records of the lab’s approval and all messages.

Sample Prep and Test Plans

You need a plan before you send samples for testing. Good planning helps you pass tests the first time. Here is an easy process to follow:

Collect everything you need for testing, like software or hardware.

Split the project into small tasks and set dates for each.

Write down all things you need, like documents and samples, before and after testing.

Make test data and keep notes about any problems you find.

Write a report that shows your results and important numbers.

This process keeps you organized and helps you meet deadlines as a children clothing manufacturer.

Understanding Test Results

You must look at your test results closely. The table below shows what you should check in your reports:

Requirement Type | Details |

|---|---|

Drawstring Regulations | No drawstrings in hoods or necks for sizes 2T to 12. Waist drawstrings must not be longer than 75mm. |

Labeling Requirements | Labels must show maker, place, date, and group. Lead limits must be followed. |

Children’s Sleepwear Regulations | Sleepwear must pass fire and chemical tests. Small parts rules are for kids under 3 years. |

You need third-party testing for CPC certification. |

If you see any problems, work with your lab to fix them before you ship. Always keep your test reports for later checks.

Tip: Go over every test report with your quality team to find problems early.

Documentation and Issuing the CPC

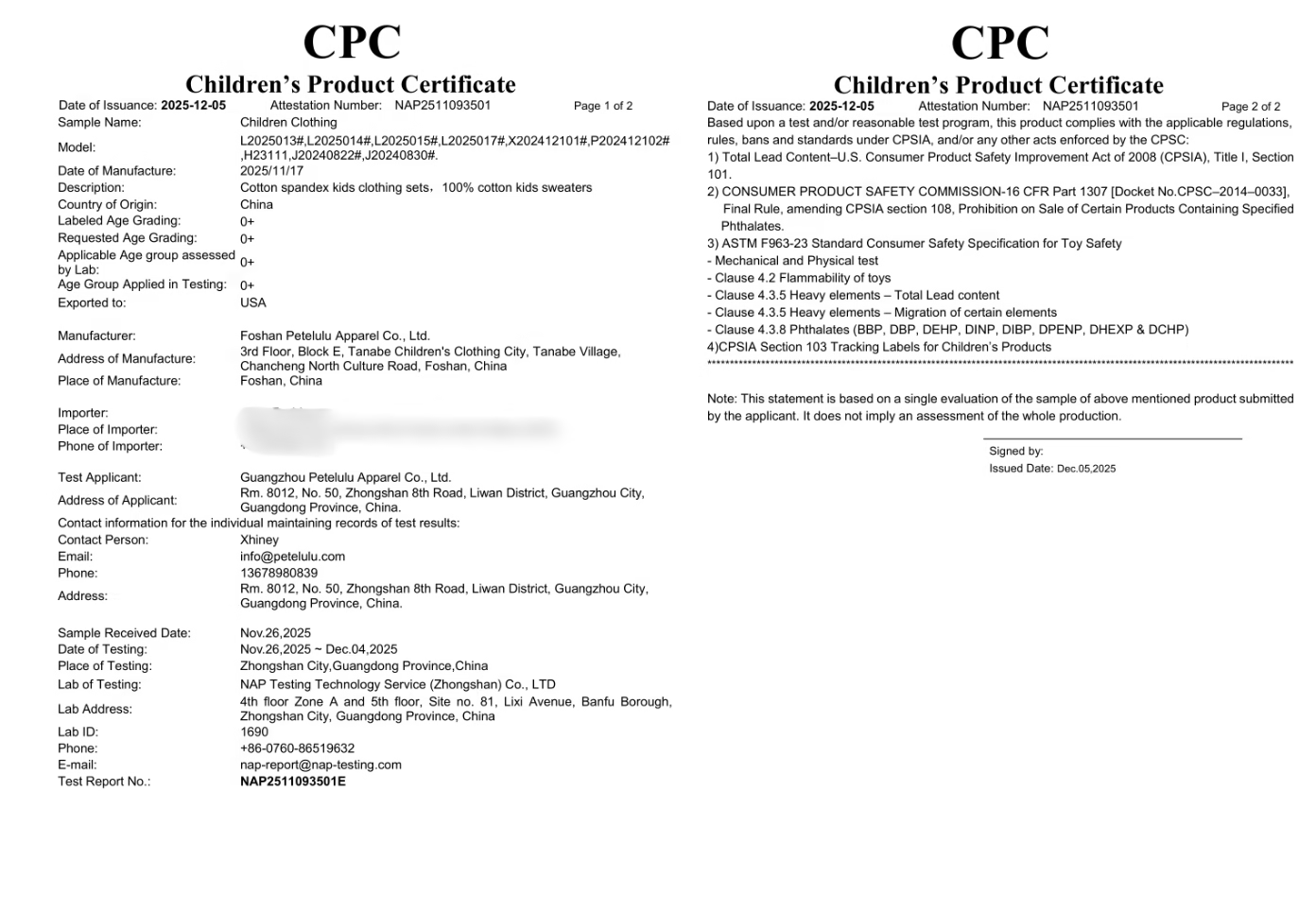

Seven Required Elements

When you make a Children’s Product Certificate, you need to include seven main details. These details show your product is safe and help you avoid trouble with stores or rule makers.

Say what product the certificate is for.

List every CPSC safety rule your product follows.

Name the U.S. importer or manufacturer who says the product is safe.

Give contact info for the person who keeps test records.

Write the date and place where you made the product.

Write the date and place where you tested the product for safety.

Name any third-party lab that did the testing.

Tip: Check every part before you give out your CPC. If you miss something, your product launch can be delayed.

Accurate Documentation Tips

You must keep your CPC paperwork clear and complete. Use detailed product names, like ASINs, to show which item you mean. List every safety rule that fits your product. Add your company’s name, address, and contact info, plus the person who keeps safety records. Always say the month, year, and place for making and testing. Include the name and contact info for the testing lab.

Component | Description |

|---|---|

Product Identification | Use clear names like ASIN. |

Safety Rule Citation | List all CPSC rules that apply. |

Importer/Manufacturer Info | Give full contact details. |

Compliance Records Contact | Name the person in charge. |

Manufacturing Date/Location | Say when and where you made it. |

Testing Date/Location | Say when and where you tested it. |

Lab Information | Name and contact of the testing lab. |

Petelulu helps you by giving certified paperwork for every batch. Our team uses OEKO-TEX, GOTS, and BSCI certificates to show your products are safe and made the right way.

Mistakes to Avoid

Many brands make easy mistakes when making a CPC. You can stop these problems by following good steps.

Mistake Description | Reason for Mistake |

|---|---|

Not making a CPC for each product type | Each color or style might use different stuff. |

Not updating the CPC after changes | New designs or suppliers need new certificates. |

Thinking similar products do not need a CPC | Materials can be different even if they look the same. |

Leaving out needed information | Missing info can stop sales on places like Amazon. |

Note: If you make children’s clothes, you must check every CPC for mistakes. Petelulu’s team looks at all paperwork and helps you avoid expensive errors.

Ongoing Compliance for Children Clothing Manufacturers

When to Retest or Update

You need to keep your Children’s Product Certificate (CPC) current. If you make a new batch that has a different date, you must update your paperwork. Every new group of products needs a fresh check. This makes sure your items always follow safety rules. Keeping your certificates up to date protects your business and your buyers.

Tip: Set reminders for each new batch you make. This helps you remember to update your paperwork and keeps your process easy.

Recordkeeping and Supplier Management

Good records and supplier checks help you follow the rules. You should:

Check supplier certificates to make sure your supply chain is safe.

Use lists to organize your papers and lower mistakes.

Keep your records for ten years, as the law says.

Update files, batch notes, and audit logs so you can trace products.

Petelulu helps you with strong quality checks and good paperwork. Our team checks every supplier and keeps careful records for each batch. You can trust our system to help you follow all the rules.

Quality Control Stage | Description |

|---|---|

Incoming Quality Control (IQC) | Check raw materials for safety and rule-following. |

In-Process Quality Control (IPQC) | Watch production steps to make sure things are done right. |

Final Quality Control (FQC) | Look at finished clothes for safety, size, and how they look. |

Petelulu uses ISO 9001 rules and supports GOTS and OEKO-TEX for organic products. Our checks help lower the chance of recalls and legal trouble.

Handling Changes and Recalls

If you need to fix product problems or do a recall, follow these steps:

Tell the CPSC about the problem within one day.

Find which products are affected using batch codes and labels.

Let customers know what to do to return or replace items.

Work with suppliers to make quality better and stop future problems.

Test products again to make sure they are safe before selling.

Tell customers about the changes and how you fixed things.

As a children clothing manufacturer, you must act fast and keep good records. Petelulu’s team helps you handle recalls and changes, so your brand stays safe and your customers are protected.

Best Practices and Petelulu’s Solutions

Case Study: Petelulu’s Compliance Journey

You can learn from how Petelulu follows the rules. As a children clothing manufacturer, you must meet strict standards. You also need to keep your work quick and smooth. Petelulu uses important steps to make sure every product meets US and world rules.

Category | Key Points |

|---|---|

Compliance Requirements | Petelulu gets certifications like OEKO-TEX Standard 100, CPSIA, and EN 16781. |

Performance Metrics | The team checks moisture-wicking, shrinkage resistance, colorfastness, and seam strength. |

Cost-Efficiency Factors | Bulk pricing starts at 500 units. Petelulu tracks all costs, including import and testing. |

Quality Assurance | Petelulu checks supplier quality with batch testing and defect tracking. |

Integration Capabilities | You get private labeling, fast design changes, and flexible lead times. |

After-Sales Support | Petelulu gives clear replacement policies and quick help for any issues. |

Petelulu’s process covers everything, from picking fabric to helping after you buy. This helps you avoid delays and makes buyers trust you.

Avoiding Common Pitfalls

You should use best practices to keep your products safe and follow the rules. Here are the top steps:

Keep all certificates ready for audits from the start.

Include all seven needed parts in your CPC.

Use simple product descriptions and list every rule.

Make your own CPC using real test reports.

Choose CPSC-accepted labs for every test.

Test again and update your CPC when you change materials.

Many brands have problems. The most common ones are:

Knowing technical details and testing ways.

You can avoid these problems by working with Petelulu. The team helps you with OEM/ODM services, safe materials, and full rule guidance. This makes your compliance journey easy and dependable.

Tip: Check your process often and teach your team the newest rules. This keeps your brand strong and your products safe.

You can get your Children’s Product Certificate by doing these things:

Use labs that the CPSC approves.

Test your products to make sure they are safe.

Collect all the papers you need.

Make your CPC and include all the important details.

Save your records for at least five years.

Your CPC must show what the product is, who made it, lab details, and proof that it meets safety rules. Working with certified experts like Petelulu helps you follow the rules and grow your brand. Check your process often and think about getting help from an expert or having an audit to keep your business strong.

FAQ

What is a Children’s Product Certificate (CPC)?

A CPC shows your children’s clothes are safe in the US. You need this paper to sell things for kids under 12. You must use test results from a CPSC-accepted lab.

How often should you update your CPC?

You need to update your CPC when you change materials, suppliers, or batches. Updating often helps you follow the rules and avoid shipping problems.

Do you need third-party testing for every product?

Yes. You must use a CPSC-accepted lab for each children’s product. Testing checks fabrics, trims, and prints. This step keeps your brand safe and protects kids.

What happens if you do not have a CPC?

You can get shipment holds, fines, or recalls. Stores like Amazon will not sell your products. You must always keep a valid CPC for every item.

How does Petelulu help with compliance?

Petelulu gives you certified materials, clear paperwork, and strong quality checks. You get help with testing, labeling, and keeping records. This makes following the rules easy and safe.