Cómo elegir la cantidad mínima de inventario adecuada: guía de una startup para reducir el riesgo de inventario

Cómo elegir la cantidad mínima de inventario adecuada: guía de una startup para reducir el riesgo de inventario

As a children’s apparel manufacturer, I’ve had the privilege of helping countless startup founders turn their dreams into a tangible product. The energy is always electric, but there is one conversation that inevitably brings a new founder back to reality: the Minimum Order Quantity (MOQ). I see the anxiety in their eyes as they worry about tying up precious capital and ending up with a mountain of unsold inventory. This is the single biggest fear for any new marca de ropa para bebés, and I’m here to tell you that with the right strategy, you can find a balance that protects your business from unnecessary risk.

Con 17 años de experiencia, petelulu ofrece una gama completa de

servicios de fabricación, desde el diseño hasta la entrega.

Empiece desde cero, cree su propia marca.

17+

al servicio de las 10 principales marcas estadounidenses

15+

al servicio de las 10 mejores marcas australianas

12+

al servicio de las 10 principales marcas europeas

Contacta con nosotros para obtener el presupuesto.👇

The Problem: The High-MOQ Dilemma and Its Consequences

For a manufacturer, a high MOQ is a matter of efficiency. We have fixed costs to set up machinery, source raw materials, and manage labor. A large order helps us amortize these costs, making the project more profitable. However, for a fledgling marca de ropa para bebés, a high MOQ can feel like a financial trap. It’s a pain point we address constantly.

-

Cash Flow Constraint: The money you spend on a high MOQ is cash that is now locked up in inventory, not in essential areas like comercialización de ropa de bebé, building your team, or developing new designs. This can stifle your growth before you’ve even had a chance to gain momentum.

-

Inventory Risk: What if a style doesn’t sell as well as you hoped? A high MOQ means you’re stuck with excess stock. This forces you into discounting, which erodes your margins and can hurt your brand image. The risk of having a “dead” inventory is a real threat to your business’s survival.

-

Lack of Agility: The fast-paced nature of the apparel market requires you to be agile. A massive, high-MOQ order can prevent you from quickly adapting to new trends or consumer feedback. By the time you’ve sold through your stock, the market may have already moved on.

Con 17 años de experiencia, petelulu ofrece una gama completa de

servicios de fabricación, desde el diseño hasta la entrega.

Empiece desde cero, cree su propia marca.

17+

al servicio de las 10 principales marcas estadounidenses

15+

al servicio de las 10 mejores marcas australianas

12+

al servicio de las 10 principales marcas europeas

Contacta con nosotros para obtener el presupuesto.👇

The Solution: A Strategic Approach to MOQ

I believe that the best approach to MOQ is not to fear it, but to understand it and use it to your advantage. Finding the right number is a strategic decision that needs to align with your business model, not just a manufacturer’s requirement. We help our partners find their “sweet spot” through a phased approach.

-

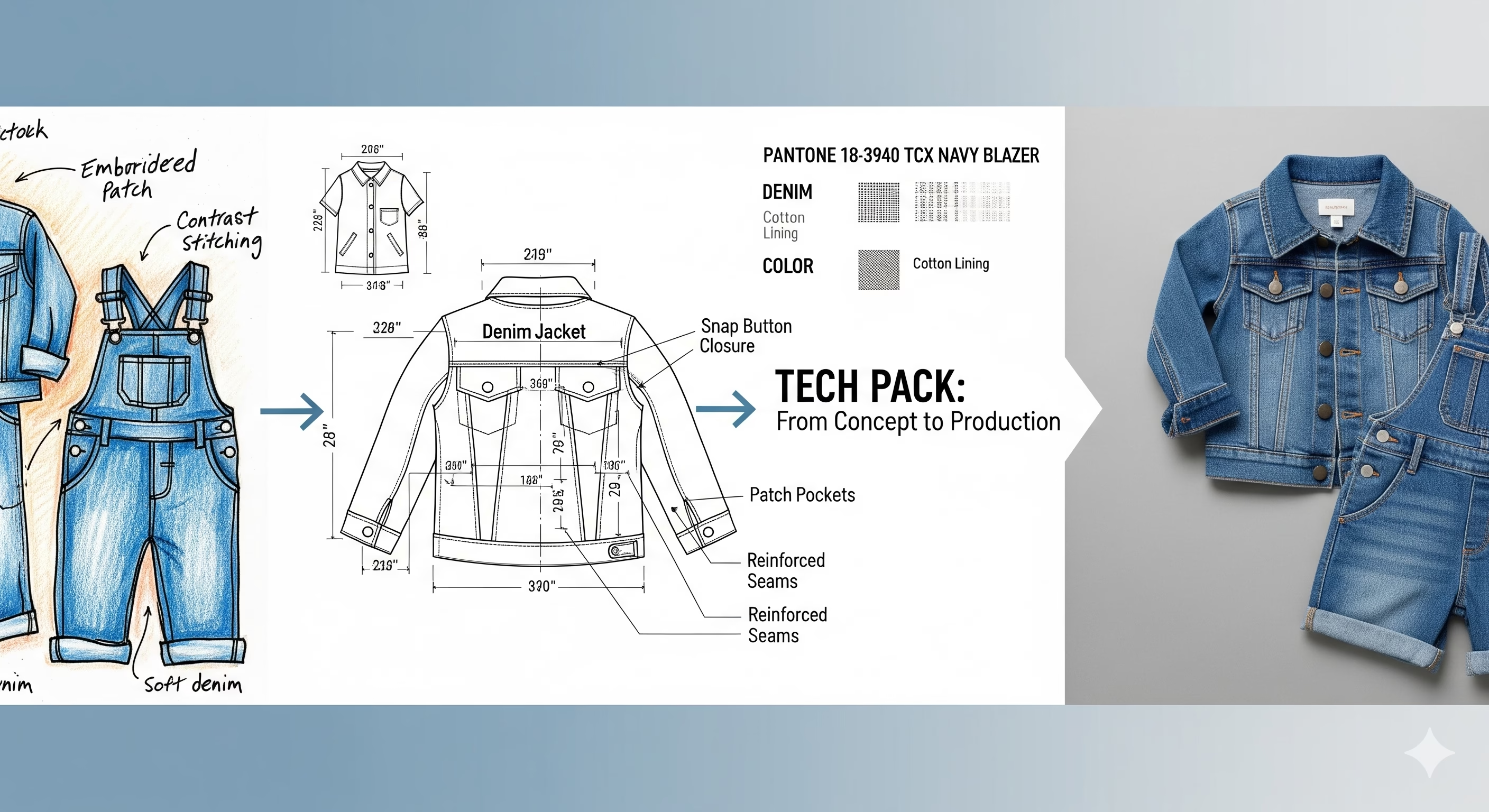

Phase 1: The Smallest Possible Order (Samples and Prototyping): Before you even think about a full run, we focus on a few samples. This isn’t about hitting an MOQ; it’s about validating your design, testing the fit and fabric, and getting initial feedback. We can’t hit a profitable price point with just a few units, but this small investment is invaluable for risk reduction.

-

Phase 2: The Initial Launch (Managed Low MOQ): Once you’ve finalized your design, it’s time to place a small, manageable order. This order isn’t about maximizing profit per unit; it’s about testing your sales channels, proving your concept, and gauging consumer demand without taking on massive inventory risk. While the per-unit price will be higher than a larger order, you are paying for the invaluable data and reduced risk.

-

Phase 3: Scaling Up (The Optimal MOQ): As you get sales data and build a customer base, you will be able to place a larger, more cost-effective order. This is where you can take advantage of economies of scale. By building a relationship and proving your sales capability, we, as your manufacturing partner, can offer you better pricing and terms, helping your business become more profitable.

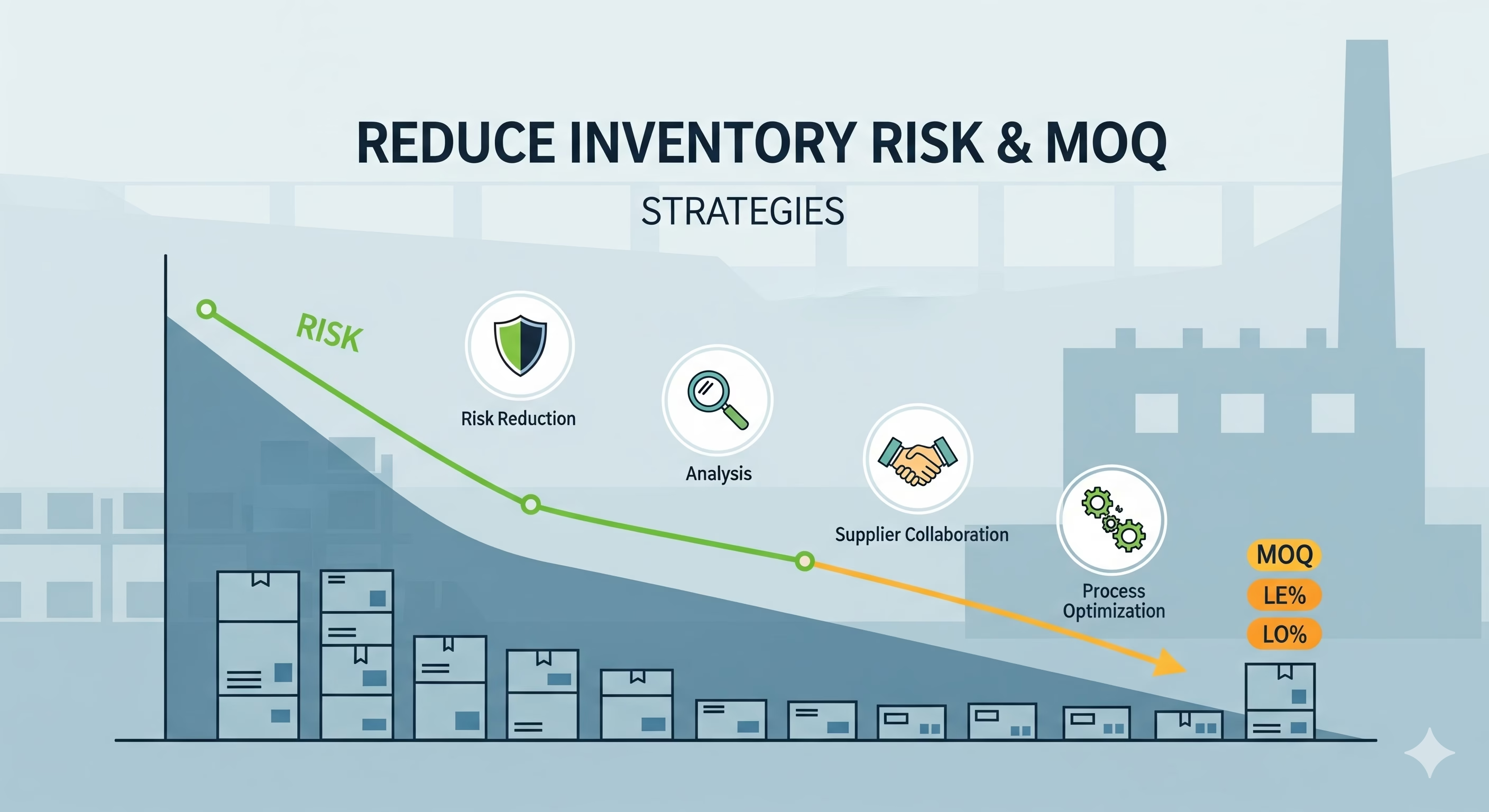

Estrategias prácticas para reducir las MOQ y el riesgo de inventario

From my years on the factory floor, I have seen some clever strategies that have helped new brands succeed.

-

Start with Fewer SKUs: Instead of launching with ten styles, focus on one or two core products that you are confident will sell. This allows you to hit a more reasonable MOQ per product, making the total order size much more manageable for a startup marca de ropa para bebés.

-

Utilize In-Stock Fabrics: Ask your manufacturer if they have any “in-stock” fabrics that you can use. Sourcing new materials often requires its own MOQ from the fabric mill. By using materials we already have on hand, we can significantly lower the MOQ for your order.

-

Build a Trust-Based Partnership: A strong relationship with your manufacturer is your biggest asset. As you grow and place more orders, we are more likely to offer flexible terms and lower MOQs because we trust you and value your repeat business. We are invested in your success.

-

Leverage Analytics: Use your sales data to make informed decisions. “By leveraging real-time inventory management and sales analytics, brands can significantly reduce overstock risk and improve cash flow,”. Don’t guess; use data to decide when and how much to reorder. This is a critical part of smart comercialización de ropa de bebé and business management.

Ultimately, navigating MOQ is about finding the right partner. My team and I are not just interested in the size of your first order; we are invested in your brand’s long-term success. By working together to strategically manage your MOQ, we can ensure your marca de ropa para bebés grows sustainably, without the burden of excessive inventory and risk.

Sobre el autor

Xhiney, fundadora de Petelulu, aporta más de 20 años de experiencia en diseño, producción y comercio internacional de ropa infantil. Colabora con Ropa infantil y Junior revistas, Xhiney lleva 17 años trabajando con marcas de ropa infantil de gama alta en Europa y Estados Unidos, ofreciendo su experiencia y apoyo.